|

| |

3. WELDING CONTROLLER CS-08

This controller satisfies the best exigencies in welding control. It is

designed for a good control of welding current through the use of a feedback

loop. It is built with a keyboard integrated in the front panel.

Main features

Storage of 60 different welding programs.

Programming by 16 buttons.

LCD Display allows displaying programmable parameters, true RMS welding

current with accuracy and other messages in process.

Built in ammeter with 5 Led 7-segment Display, showing for each

spot the welding time in cycles and the true RMS welding current in kA. The

ammeter can monitor the welding current and can display the current of each

half cycle of the weld on LCD. On each weld spot the ammeter can perform

self-calibration in order to provide high accuracy for the measured current.

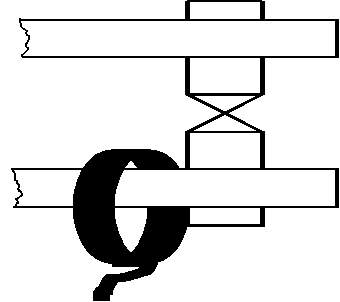

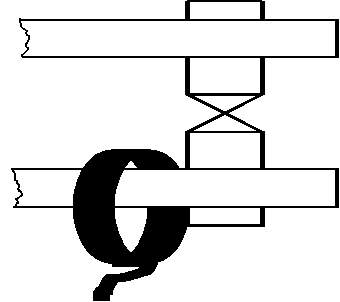

The welding current is measured using a toroidal coil placed in the

secondary circuit.

Toroidal coil placed in the secondary circuit

Constant current operation. The operator directly presets the value

in kA of the desired welding current. CS-08 keeps the preset value, checking

for each cycle and modifying the welding current if necessary.

Stepper function compensates for variations of the welding quality due to

the electrodes wear. Welding current will be gradually increased according

to electrodes diameter enlargement.

2 solenoid (optionally 4) valve 24Vdc 7.2W for pneumatic circuit.

A welding diagram for spot and projection welding.

Counter for executed spot.

Optionally RS 485 allows connecting with a computer for programming and

other functions.

On demand it can be build with up to 4 additional inputs.

Direct drives thiristors up to 700A.

|