Welding controllers, WELDING DIAGRAM

The welding controller CS02 has a simple diagram with a squeeze time, a weld time, a cool time and one welding current during the weld time.

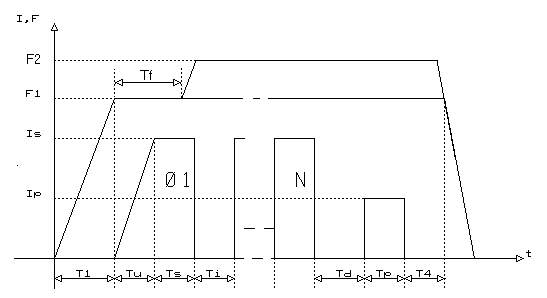

The CS05 or CS08 welding controller can achieve many different diagrams depending on the welding which it will be check. An example for CS08 and CS05 is showed in the following diagram for the spot or projection welding. The main different between CS05 and CS08 is achieving of welding current.

Spot and Projection Welding Diagram

| Parameter | Meaning, explanations | Value |

| T1 | Squeeze time: The electrodes come closer because of a force generated by the pneumatic circuit. The value of this time will be chosen so that the welding current will start when the squeeze force is normal. This time begins immediately after the welding process has started. | 0.. 99 cycles |

| Tu | Up slope time: This time allows an increase of the current from the zero value to the preset value Is. | 0.. 99 cycles |

| Ts | First weld time: In this time the preset value Is weld current is present. This time is also a welding impulse made of N preset impulses. As this is an important time it is displayed in the working state, too. | 0.. 99 cycles |

| Ti | Hold time between impulses: It is necessary if several welding impulses are used, that is if N is different than 1. If N=01 its value will be ignored even if it is preset as different than zero. | 0.. 99 cycles |

| Td | Hold time: It is used at the secondary welding current. | 0.. 99 cycles |

| Tf | Secondary solenoid valve time | 0.. 99 cycles |

| Tp | Second weld time: In this time the preset value Ip weld current is present. | 0.. 99 cycles |

| T4 | Cool time: In this time the electrode pressure is maintained. | 0.. 99 cycles |

| Is | First weld current: The current value

can be adjusted in two ways:

|

|

| Ip | Second weld current:The current value

can be adjusted in two ways:

|

|

| N | The number of welding pulses | 0.. 25 |

We can design this sequence in order to fit your actually needs. From this basic welding diagram, we implemented our welding controllers: